CAMX Paper Published: The Convergence of Composites & Topology Optimization

Ushering in the Next Era of Aircraft Lightweight Structures

Introduction

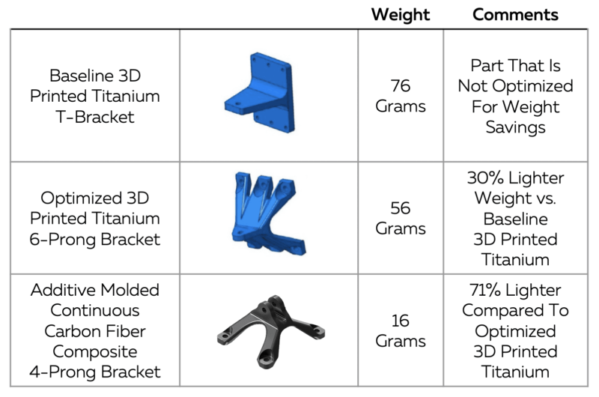

The A350XWB and B787 programs are the first large-scale commercial programs to develop composite-intensive aircraft with a composition of about 80% composite materials by volume [1]. Reports on the costly investment of these clean-sheet designs [2] suggest that next-generation aircraft structures will likely be based upon derivatives of these models. Yet light-weighting challenges still abound within these programs and the upcoming ones. Particularly for brackets whose function is to transfer load from one mechanical interface to another.

These aerospace applications still lack a complete advanced composites solution. While commercial support of simulation tools is currently emerging for metallic additive manufacturing processes, advanced composites manufacturing processes still lack such support. For instance, most leading vendors of finite element analysis packages have recently added topology optimization features for isotropic materials, yet topology optimization for fiber-reinforced composite structures is still not supported.

On the academic front, several research papers have already focused on topology optimization of continuous fiber-reinforced composites [3-4] and the academic community appears to have settled on a few benchmark problems, like the three-point flex problem, so-called the MesserschmittBölkow-Blohm (MBB) beam. However, these problems are simplified for purposes of benchmarking. Thus, the challenge of applying topology optimization and finite element analysis techniques to aerospace composite structures remain.

This paper aims to explore the potential benefits of applying a simultaneous topology and fiber orientation optimization toolset to 3D aerospace composite structures.

Read Whitepaper: compositesworld.com/cdn/cms/arris_composites_paper_camx_2020.pdf