Consumer

Electronics

Do more with less

1

Improved drop and impact resistance

2

Lighter, thinner, and more compact

3

More integrated functionality

The Way It Is Now

Electronic devices touch every part of our personal and professional lives, and designers constantly strive to make them smaller, thinner, lighter, and tougher. But brands are held back by conventional manufacturing techniques. To build the next generation of consumer electronics, we need a new approach.

Where We Are Going

By integrating electronics and metal components into strong, lightweight, topologically optimized composite structures, ARRIS empowers consumer brands to pack powerful functionality into smaller and lighter packages. We’re redefining the possibilities of product architecture, aesthetics, and performance.

Consumer Electronics Examples

1

HIGHLY INTEGRATED COMPOSITES

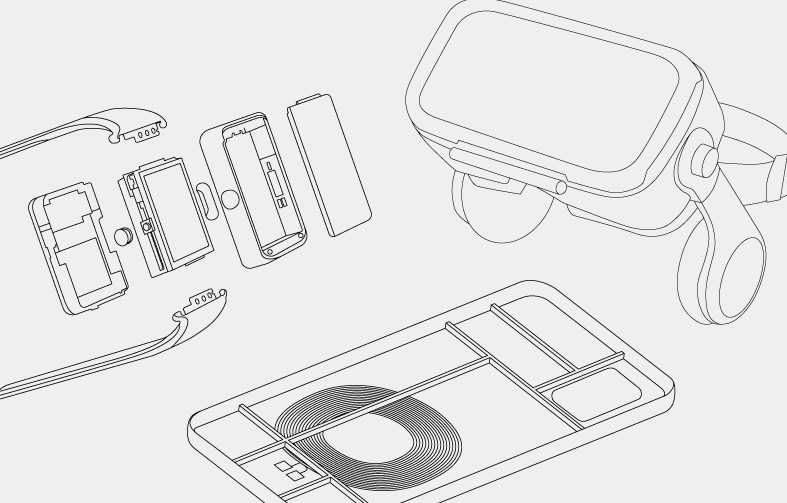

Traditionally, adding wireless charging to a mobile device requires multiple new components, increasing the weight, thickness, and potential points of failure. ARRIS allows charging coils and related electronics to be integrated directly into a phone’s ultra-thin enclosure, enabling brands to deliver next-gen functionality without compromising design or performance. Using precisely aligned carbon and glass fibers along with thermoplastic resins and advanced molding techniques, ARRIS delivers durability, functionality, and consumer-grade CMF at scale.

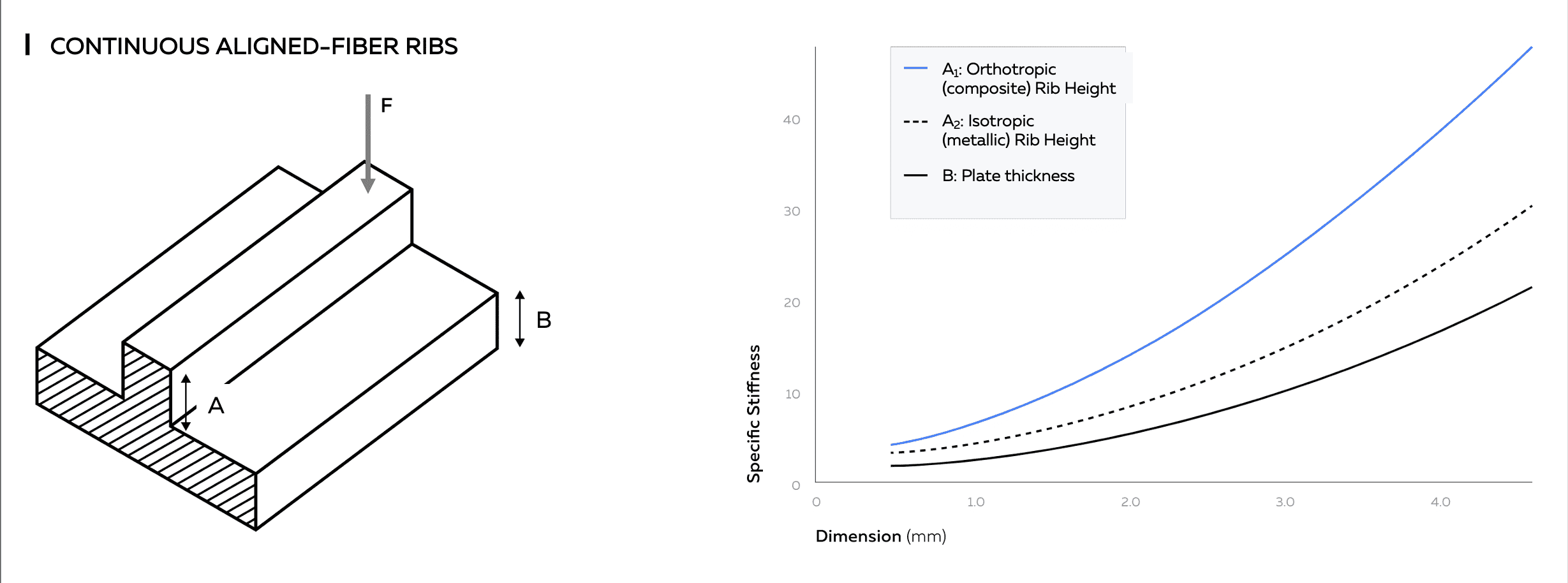

Material-efficient structures are fundamental to highly integrated electronics design. As illustrated below, continuous aligned-fiber ribs are the optimal way to increase the stiffness and performance of electronics products.

Material-efficient structures are fundamental to highly integrated electronics design. As illustrated below, continuous aligned-fiber ribs are the optimal way to increase the stiffness and performance of electronics products.