ARRIS’ Additive Molding™ is an automated manufacturing technology with new material and design latitudes that expand the possibilities for products across industries. 3D-aligned continuous fiber composite materials are now possible within complex shapes where material composition can change within regions of a single part. Ultimate performance meets ultimate scalability.

Additive Molding™

Ultimate Performance & Scalability

Performance

Design: Topology-optimized, material-efficient structures

Multifunctional: Material combinations and highly integrated designs

Embedded: Electronics, circuits, and metallic components

Scalability

Optionality: Wide range of material options, global supply chains

Cosmetics: High-quality molded surfaces and tolerances

Production Ready: Repeatable process, reliable equipment

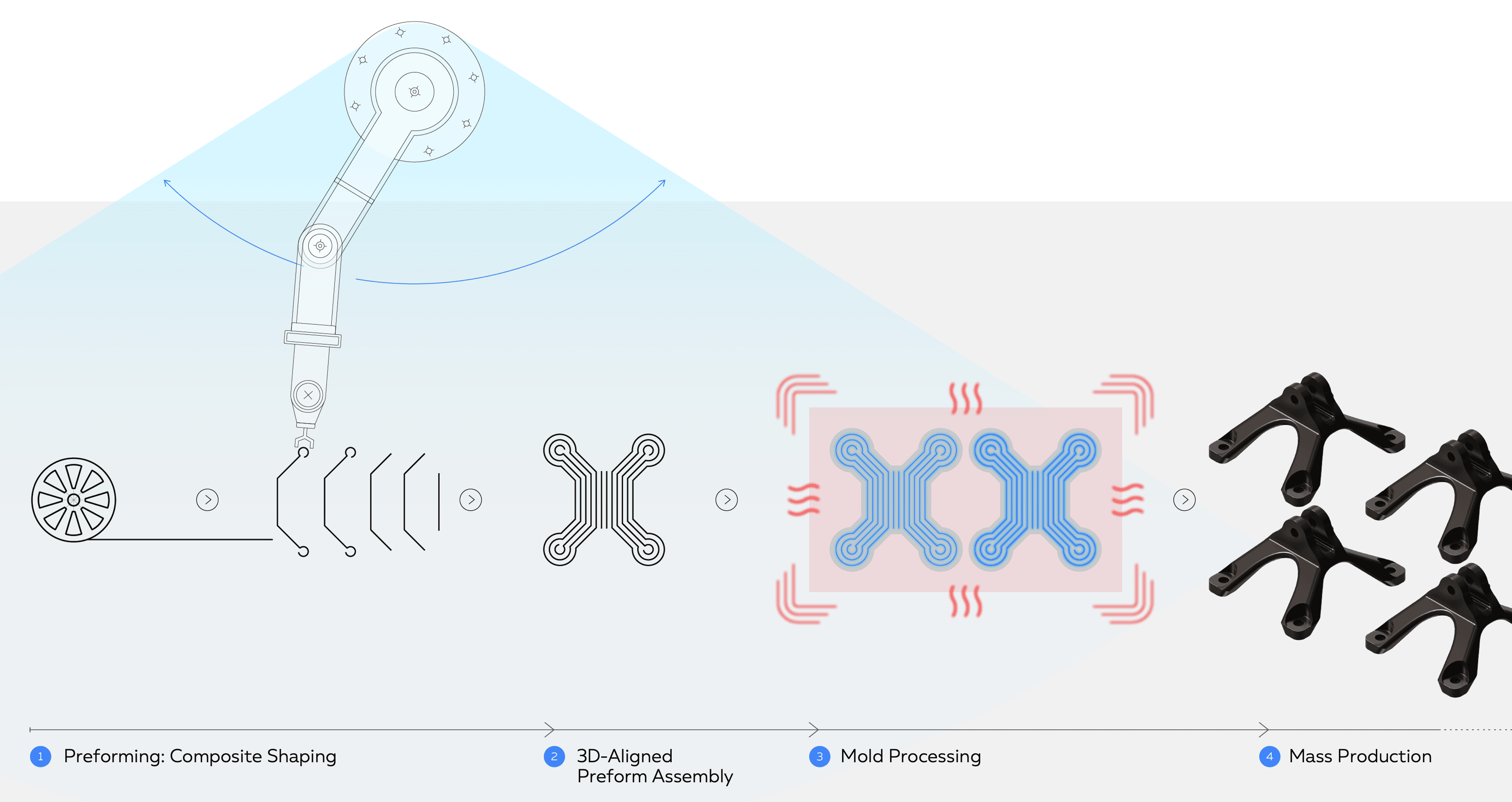

How Additive Molding™ Works

ARRIS’ patented Additive Molding™ technology automates the additive manufacturing and molding of complex products made of continuous 3D-aligned fibers (e.g., carbon and glass), thermoplastics, and components (e.g., circuits, electronics, and metallic inserts).

Continuous dry fiber is impregnated with thermoplastic resin and then shaped to comprise a section of the final part. These shapes have continuous composite fibers aligned with the part’s 3D stress-vectors.

All shapes and components are assembled into a final assembly.

Final processing of assembly locks in ideal performance, accuracy, surface quality, and part-to-part repeatability.

What Can Additive Molding™ Do for Your Product?

Resolution & Precision

Cosmetic Surfaces

Multi-material

Large Parts

Manufacturing Scale

Sustainability

Built on proven technologies

Composites Manufacturing, Additive Manufacturing

High-Speed Molding

Grounded in proven legacy technologies trusted by the world’s leading manufacturers, Additive Molding™ delivers ultimate performance with aerospace-developed material processing approaches and unparalleled design capabilities. In addition, it is a scalable, high-speed manufacturing technology based on mature, high-volume molding approaches.

Leveraging deep experience in material sciences, composites, and thermoplastic processing, ARRIS empowers leading brands to create innovative, high-performance, sustainable products at scale using fiber and topologically optimized-for-the-process designs.

The product design and engineering teams of top brands shoulder great responsibility. Manufacturing scalability and quality are required because companies cannot fail their loyal customers. Product performance and design differentiation are necessary to attract new clients and inspire existing customers. Additive Molding™ brings together scalability, performance, and design for these teams in the ultimate manufacturing technology.

Partner with ARRIS

ARRIS’ applications development team leverages deep expertise in additive manufacturing, composites manufacturing, and product development across industries. This world-class team is equipped with ARRIS’ powerful SpecificDesign™ design and optimization software, and is exclusively focused on helping customers’ product teams create breakthrough products.

New client onboarding generally follows this process:

Reach out to learn more about how Additive Molding™ can differentiate your products.

Contact Us