JUNE 26, 2025: SPECIALIZED + ARRIS

Roval Rapide CLX Wheelsets with ARRIS Carbon Fiber Spokes

Meet the Roval Rapide Sprint CLX and CLX III featuring Roval By ARRIS Carbon Fiber Spokes [ READ ]

Cycling Weekly Article /// Road.cc Article /// Velo Article

An all-out effort for the all-in ride… send it.

Risk-taking runs through our veins, and that’s how we’ve journeyed to this point as the creators of a cutting-edge technology (Additive Molding) that achieves what was once considered impossible. Yet, our obsession with advanced composites is only part of what led us to create the next generation of carbon fiber spokes—we love to ride, and our affinity for all things bicycles sparked us to make the kind of spokes we’d actually rely on ourselves. We’re those people. The kind who confront the fearful misconceptions of what could go wrong with the daring belief in what could go right.

Performance is our commitment, and the ride is yours.

We’re not new to the bicycle space, personally and professionally. Founded in Berkeley, CA more than five years ago, the ARRIS team has challenged what’s possible with continuous fiber composites in nearly every industry, including high-performance sports. Our sweet spot is designing and producing the highest-performing components at the lightest weight. Not only do we have our own first-of-its-kind manufacturing and software technology, but we also develop and manufacture our own thermoplastic composite materials. Give it your all, or don’t bother, right? That’s why we work with many of the most innovative brands in the world. But this time, we made something special to satisfy our selfish interests, yet it quickly became something we couldn’t keep to ourselves. Let’s be real… we’re all pushing boundaries for the ride.

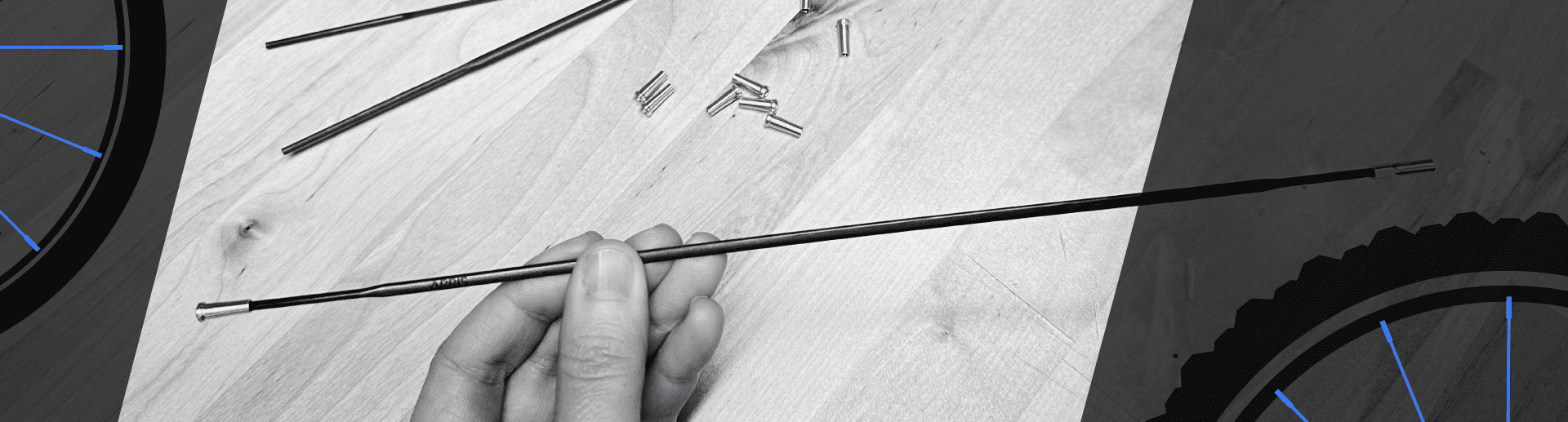

Video Series: Proven in the lab, proven on the trail.

Designed and developed by advanced composites experts at ARRIS headquarters in Berkeley, CA, these award-winning carbon fiber bicycle spokes have also been put to the test again and again. Explore the video series to learn more.

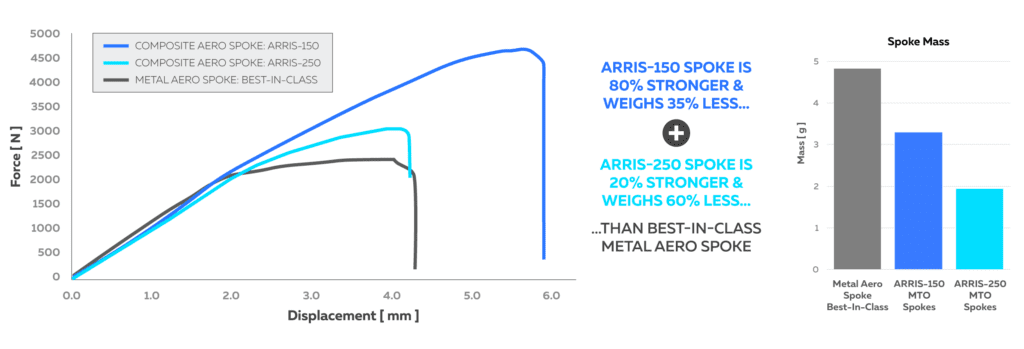

THE RESULTS: THERMOPLASTIC CARBON FIBER SPOKES

The product line-up includes multiple options to meet industry-leading bicycle brands’ highly competitive weight and performance requirements. For example, one of the ARRIS spokes we offer is 2.7x stronger gram for gram than the best-in-class metal aero spoke available in the market today.

FREQUENTLY ASKED QUESTIONS

Where can I get a product data sheet for the ARRIS | MTO Spokes? Let’s talk! But all good conversations start with an NDA.

Can I purchase the ARRIS | MTO Spokes today? Not yet, but we’re taking orders. ARRIS is working with bicycle brands directly, but don’t hesitate to let your favorite distributor or wheel builder know you’re interested in our spokes.

When will I see ARRIS | MTO Spokes in the wild? Soon… very soon.

ABOUT ARRIS

Founded in 2017, the team developed Additive Molding, a patented software, materials, and manufacturing technology that enables continuous fiber thermoplastic composite parts at scale across industries (e.g., portable electronics, performance footwear, bicycles, automotive, aerospace, industrial, etc.).

- ARRIS + AIRBUS /// Composite Research Collaboration [ READ ]

- ARRIS + NORTHROP GRUMMAN /// Next Era of Lightweight Structures [ READ ]

- ARRIS + BROOKS /// Forbes Interview: Cutting-Edge Running Shoes [ READ ]

- ARRIS + BROOKS /// Tech Partnership with Market Leader [ READ ]

- COMPOSITES WORLD /// Cover Story: Factory Tour with Jeff Sloan [ READ ]