Lightweighting Rock Climbing Gear with ARRIS Chief Engineer

Passion for Rock Climbing & Cutting-Edge Composites Leads To 30% Lighter Cam with Additive Molding

Erick Davidson, Co-Founder and Chief Engineer of ARRIS, began climbing about 20 years ago, focusing on crack climbing outdoors. Although not much of an off-width climber, he started making large cams to ensure his fellow climber and wife felt safer in wide cracks.

Davidson, who leads the design, simulation, prototyping, and tooling teams in Berkeley and Taiwan, did his Master’s work in composites at UC Berkeley. He gained experience at several technology start-ups before co-founding ARRIS. During the early days at ARRIS, he also founded a small company specializing in the fabrication of very large cams for the climbing community.

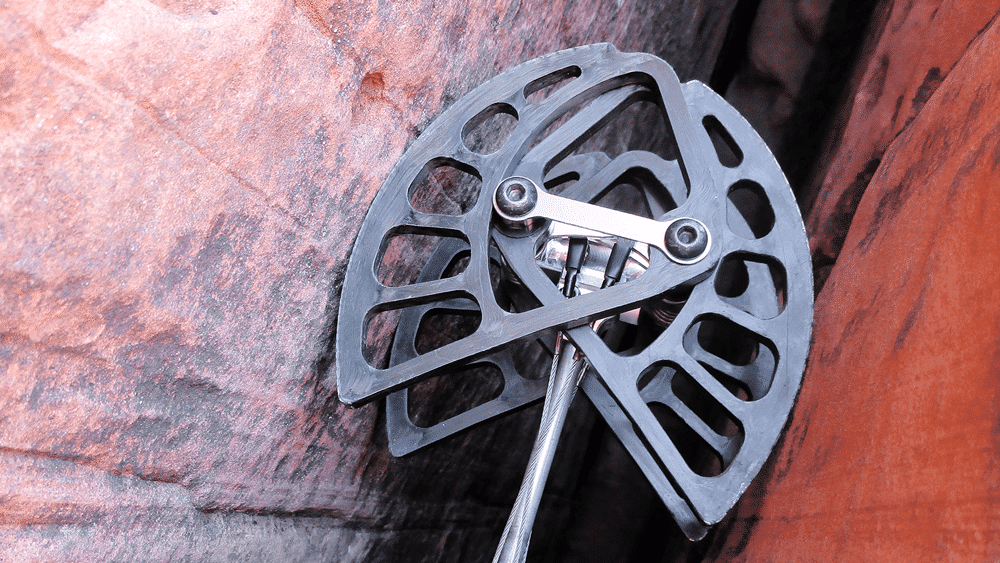

Traditionally, cam lobes are made from aluminum due to its frictional properties and high-specific strength.

“Climbers are always after lighter gear, so composites seemed like a natural fit, but there wasn’t a composites technology suitable for making cam lobes until ARRIS,” said Davidson. “I immediately recognized the potential of the technology for making cam lobes as they appear to be an ideal geometry for aligned continuous thermoplastic composites, but a few years passed before I took on the challenge as a personal project.”

After making and testing a few carbon fiber cams in the lab on the weekends, Davidson knew he had to get outdoors for the real test. Planning a week-long climbing vacation, Davidson and his wife decided to venture farther than their usual weekend destination, Yosemite. They chose Red Rocks near Las Vegas, a familiar spot with great cracks, ideal for testing the carbon fiber cams.

“Having tested the cams in the lab and seeing them perform well, I was confident they would perform outdoors,” said Davidson. “Still, the lab testing is an idealized setup, so you can never be entirely sure without doing some actual climbing.”

Davidson’s wife, the avid off-width climber, went after challenging pitches with the ARRIS carbon fiber cams and experienced no issues with handling or placement. The cams were so light she had to double-check to ensure she had selected the correct one.

He’s enthusiastic about the significant weight savings achievable with the new carbon fiber cams without compromising performance. Typically, weight reduction in climbing gear is incremental, but this innovation represents a substantial leap.

“At 30% weight savings,” said Davidson, “these carbon fiber cams weigh less than the next smaller size aluminum cams.”

Additionally, Davidson is pleased with the performance of the integrated aluminum friction strip. The aluminum interface, essential for its friction and wear properties, is co-molded onto the carbon lobes and has exceeded his expectations.

At ARRIS, the company embodies a very active culture because many of its team members enjoy outdoor activities such as climbing, mountain biking, skiing, hiking, and running. Team members take great pride in working on projects related to these pursuits, and throughout the years, ARRIS has developed various propulsive plates for performance footwear, such as the Hyperion Elite 4 by Brooks Running, and mountain bike parts, including the ARRIS | MTO carbon fiber spokes. In the same spirit, the team has also had fun creating a minimalist phone case that has proven incredibly durable throughout the last 5+ years and is making a comeback soon.

“To find innovative solutions to these types of projects, you have to have an intimate knowledge of the use case,” said Davidson. “Climbing cams are definitely a challenging use case. You have to trust cams to protect you from potential serious injury or even death in a fall, but they also have to withstand a certain amount of abuse inherent to the environment. And, it took time to determine how to make these robust enough to trust them. The thermoplastic matrix exhibits the toughness required for this application.”

The ARRIS team is made up of many highly motivated experts across a wide range of technical disciplines who like to work on projects that directly impact their lives. That’s the story behind ARRIS | MTO spokes recently featured in the March 2024 edition of Bicycle Retailer. Davidson, who actively seeks ways to improve gear and finds motivation to work on these kinds of challenges, considers himself fortunate that lightweighting cams turned out to be an excellent application for the ARRIS technology.

Davidson and his wife have several climbs lined up in Yosemite that will make good use of this cam, and they are eager to test the cam again and again. In the fall, they plan to visit Indian Creek, known for its abundance of 5″ splitters, which will provide ample opportunities to test the ARRIS cam.

He plans to do more lab testing and extensive practical testing on future climbing trips. While some minor adjustments are being made to the ARRIS cam lobe, Davidson is equally excited about replacing other metal cam components with carbon to make the cam even lighter.

Let’s Connect: Talk with the ARRIS team today—schedule a discovery call or request a facility visit by reaching out using our contact us page.

Media Inquiries: Contact media@arriscomposites.com