Design, engineering, and manufacturing typically involve a lot of compromises, requiring complex assemblies of distinct parts and materials to make intelligent, high-performance products. Until now.

業界已經通過驗證的材料

以前所未有的方式使用

棱合的Additive Moulding™技術得以將世界上最先進的材料 - 連續碳纖維、凱夫拉爾纖維或玻璃纖維,以及廣泛的工業熱塑性塑料與埋入式金屬和電子零件整合到單一部件中。 這種以獨特的方式結合各種材料與零件的製造工藝,可以使世界一流領導品牌得以大量生產具有更高水準性能的產品。

1

廣泛的材料選擇範圍,可滿足任何應用需求

2

透過獨特的多種材料整合製程生產多功能零件

3

可靠的供應鏈與經過驗證的材料,具有最好的性能/成本選擇性

連續纖維

1

PERFORMANCE AT SCALE

碳纖維,凱夫拉爾纖維和玻璃纖維輕巧、堅硬且堅固-在相同重量下,其性能遠遠超過任何金屬或射出成型材料。 從歷史上看,設計限制、製造效率不彰和可擴展性缺陷限制了這些最佳材料的使用。

諸如碳纖維、凱夫拉爾纖維和玻璃纖維等連續纖維複合材料擁有比任何金屬或射出成型材料更大的剛性和強度重量比。目前對準排列纖維的技術僅僅運用在飛機或超級跑車上,而大眾市場產品的應用仍然是遙不可及的。 棱合的Additive Moulding™有效地對齊複合纖維並製造出了性能無與倫比的部件。

1

最高的材料強度與剛性重量比

2

廣泛的材料屬性

3

高能量吸收和耐腐蝕性

熱塑性塑料

2

BETTER BY DESIGN

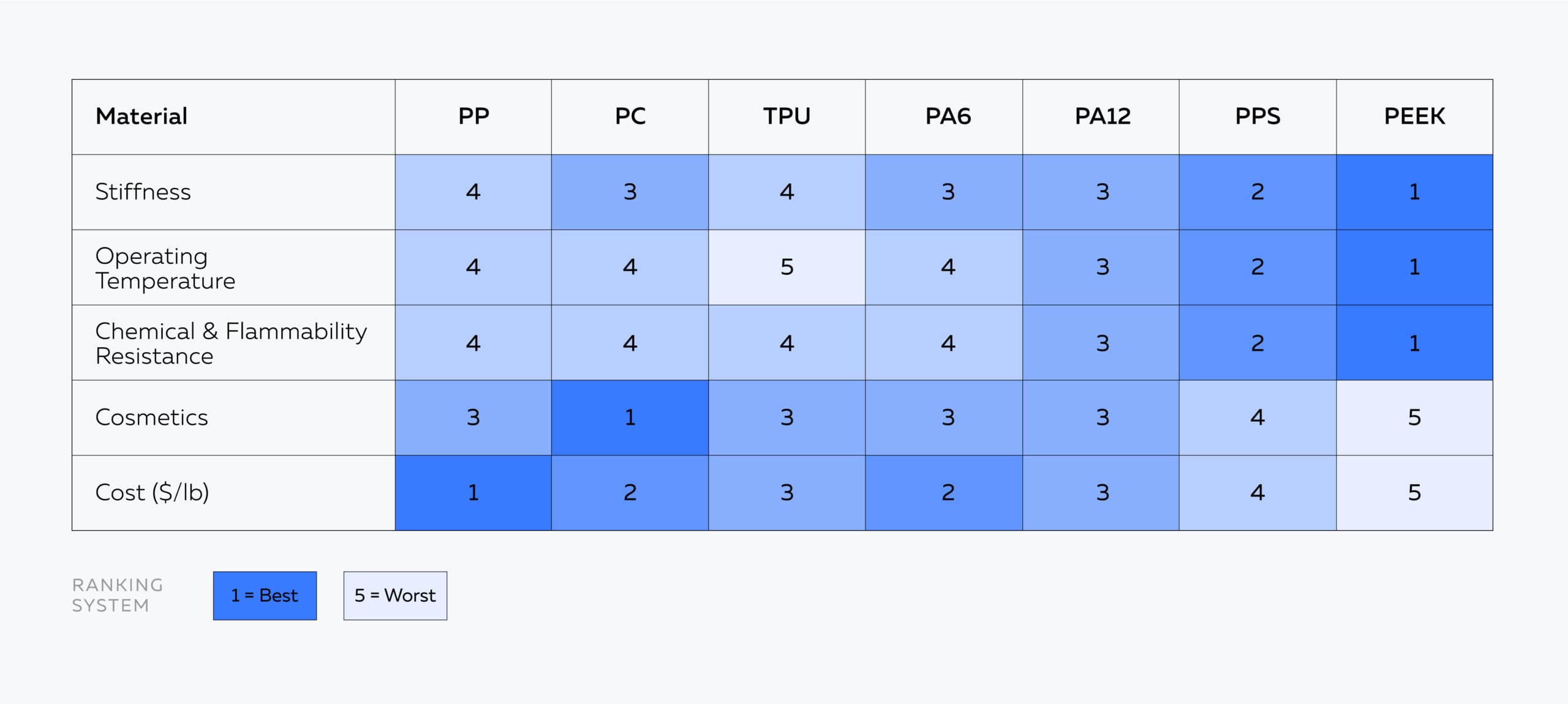

無論任何工程與環境的挑戰,棱合的熱塑性塑料都可以提供解決方案。棱合針對每種不同的應用和環境需求,使用最佳的熱塑性塑料。

大多數連續纖維複合材料的發展仍受限於熱固性樹脂體系。 熱塑性模塑革命性的發展為複雜、堅韌和可回收產品的大量生產打開了大門,但是複合材料業界在熱塑性塑料上發展依然十分緩慢。 與熱固性樹脂不同,熱塑性塑料可以快速生產,無需較長的固化時間,並且減少浪費和能源使用需求。

棱合改變了複合材料應用的範疇,並幫助頂尖品牌利用各種熱塑性複合材料的多用途特性,製造出更美觀、堅韌、可回收和可擴展的產品。

棱合改變了複合材料應用的範疇,並幫助頂尖品牌利用各種熱塑性複合材料的多用途特性,製造出更美觀、堅韌、可回收和可擴展的產品。

1

製造速度與外觀品質

2

可回收性和可持續性

3

堅韌

連續纖維+熱塑性塑料

3

製造,重新定義

設計人員現在可以結合連續纖維的性能以及熱塑性塑料的多功能性。隨著高性能航太複合材料技術與大量成型生產能力的結合,以複合材料取代金屬零件的時代已經來到

數十年來, 航太工業領導者一直在尋求熱塑性複合材料的韌性和優勢。這些材料開發的努力已成為下一代複合材料的基礎。 儘管熱塑性材料具有理想的材料特性,但有限的製造能力減緩了其應用。棱合Additive Molding™ 重新定義遊戲規則,使設計師和工程師得以在複雜的產品設計中利用熱塑性塑料的易量產性和優勢以及連續纖維對準排列的性能。

通過在熱塑性樹脂中精確地對齊連續纖維,棱合提供的下一代複合材料,具有無與倫比的機械性能和以前無法達到的量產規模。 因此,金屬被取代的新時代已經到來,以更優質的複合材料設計來取代過去機械加工,積層製造/ 3D打印,金屬鑄造,金屬注塑成型和金屬包覆成型的產品。

通過在熱塑性樹脂中精確地對齊連續纖維,棱合提供的下一代複合材料,具有無與倫比的機械性能和以前無法達到的量產規模。 因此,金屬被取代的新時代已經到來,以更優質的複合材料設計來取代過去機械加工,積層製造/ 3D打印,金屬鑄造,金屬注塑成型和金屬包覆成型的產品。

1

複合材料可在多種應用中取代金屬

2

大眾市場產品達到更高水準的性能

3

新設計來自各個產業的領先創新者

埋入式元件

4

BEYOND MECHANICAL

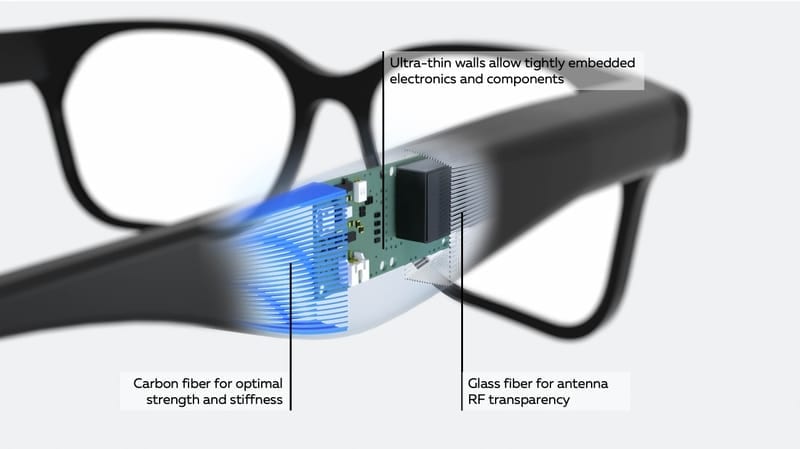

Product design engineers pay close attention to material properties in an ongoing pursuit of the right component design, made of the right material, in the right place to meet a product's various functional requirements. But what if engineers could specify different material properties, within regions of a single part? With Additive Molding™ they can. As a result, the product improves in two important ways: the part count goes down and the performance goes up.

ARRIS' continuous fiber composites outperform all other materials while providing the ultimate in cost-effective scalability. But with Additive Molding™ , that’s just the beginning. Designers can also integrate multifunctional materials — such as metallic threaded inserts or pins, RF transparent windows, thermal insulation or heat sinks, or tough impact zones — into their products.

Even functioning electronic components can be embedded into lightweight composite structures, allowing wires and circuits, sensors, and antennae to be integrated seamlessly.

Even functioning electronic components can be embedded into lightweight composite structures, allowing wires and circuits, sensors, and antennae to be integrated seamlessly.

1

Highly suited to highly integrated product design

2

The thinnest walls and features enable the most compact designs

3

Embedded electronics like wires, circuits, sensors, and antennae

Multifunctional performance through material combinations

聯絡我們

Ask us more about our materials options and how to select the best combinations to solve your toughest design and engineering challenges.

聯絡我們