ARRIS & Skydio Redefine Aerospace Design to Achieve Ultimate Lightweight Performance

Additive Molding™ is taking commercial drones to new heights

If you want to see the future of aerospace innovation, look no further than Skydio.

The Silicon Valley UAV pioneer’s self-piloting drones use a revolutionary AI to follow objects and dodge obstacles, delivering “impossible video” capabilities. Imagine a drone following your bike on an invisible leash, effortlessly ducking low-hanging branches, as you race down a tricky single-track, for instance. It’s easy to see why one industry review described Skydio’s autonomous flight capabilities as “indistinguishable from magic”.

But Skydio’s commitment to cutting-edge technology doesn’t end with their software. For their new Skydio X2 drone, they’re also using ARRIS’ Additive Molding™ technology to completely reimagine the way it’s designed and manufactured. The result: a lighter, stronger, more capable UAV for industrial and enterprise customers to use across a range of highly demanding environments.

Partnering with ARRIS empowered Skydio to deliver breakthrough hardware innovation at an incredible pace. It also offers a glimpse into the future; how novel materials and advanced manufacturing technologies will transform the aerospace sector. Let’s take a closer look.

Lighter, faster, further

Like any flying vehicle, the Skydio X2’s capabilities are ultimately limited by weight. The heavier a drone, the more energy needed to provide lift and move it through the air. In other words: heavier equals lower, slower, and shorter flights.

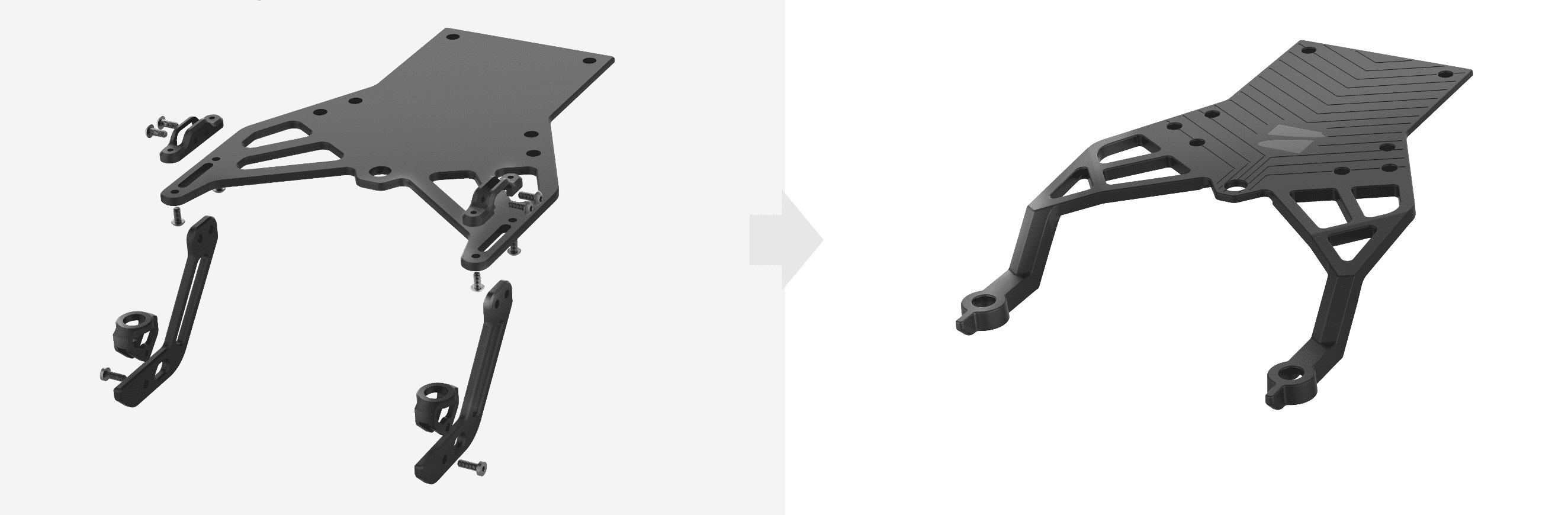

By using Additive Molding™ technology, Skydio was able to craft the X2’s upper airframe structure using continuous carbon and glass fiber composites — the same high-performance materials used in jets and race cars. Because continuous composites surpass the strength and stiffness of titanium at less than half the weight, it is the go-to material wherever weight savings is valuable. However, the design limitations and inefficiencies of legacy composites processes – usually stacking sheets of fiber and cutting or machining away scrap material – resulted in Skydio’s prior composite upper structure requiring assembly of 17 different pieces:

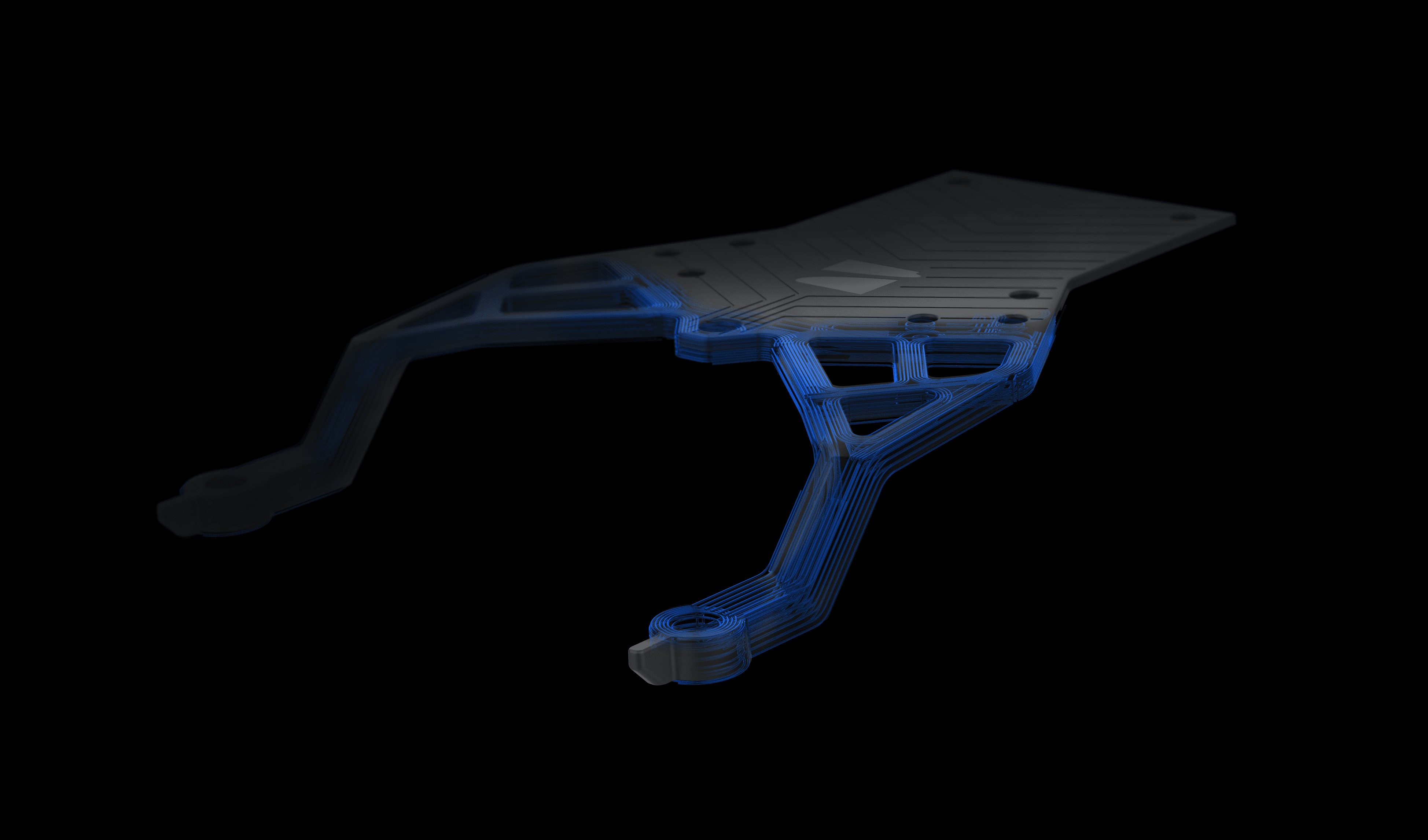

Because Additive Molding™ allows 3D-alignment of continuous fibers within topology optimized structures, Skydio was unshackled from the constraints of legacy composites to reimagine their airframe design. With carbon fibers precisely tuned to deliver strength and stiffness where needed most, extraneous material, cut fibers, joints, and attachment features were all eliminated to deliver a single, ideal structure.

Multi-Material Advantage

Like any advanced aircraft, Skydio’s drones are built with careful attention to the individual function of every region of the product. For most drones, this multi-functional optimization means assembling many components from different materials – adding time, expense, complexity, and risk to manufacturing supply chains. Large complex assemblies also drive up the size, weight, and potential points of failure.

Additive Molding™ provided the technical solution: in addition to carbon fiber, ARRIS can integrate other types of fiber, different thermoplastics, electronics, and metallic inserts, all directly into a single part ensuring optimal use of every millimeter of space and gram of weight. ARRIS provided the supply chain solution: compressing a complex, multi-tiered Asia-based supply chain, and bringing it back to the US.

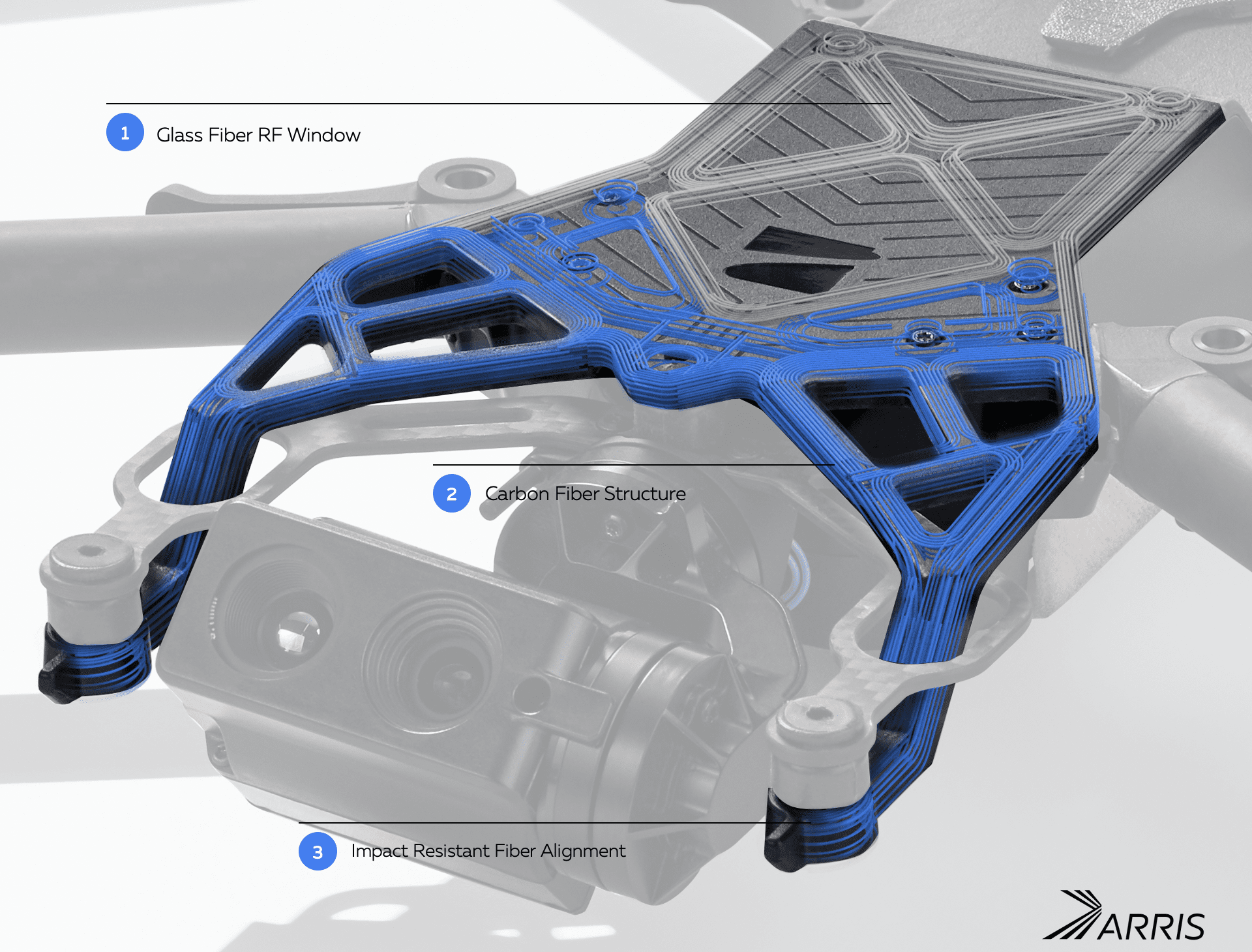

As we helped Skydio design and manufacture the monocoque X2 airframe structure, we enabled multi-functional performance through multi-material optimization:

- RF-transparent, glass-fiber windows were positioned around GPS electronics for unobstructed communication

- Highest strength and stiffness carbon fiber was aligned through the arms that hold, precisely position, and protected the optical equipment

- An impact-resistant aligned-fiber construction reinforced the ends of the arms

- Resin-rich surfaces allowed the molding of both gloss and satin Class-A surfaces without the need for post-processing.

Accelerating innovation

At ARRIS, we’re working with some of the biggest names in aerospace to develop lighter, more sustainable aircraft. But by their nature, aviation giants are slow-moving with 10+ year-long product development cycles. Skydio was able to implement Arris technology from first concept to production on a major redesign in under 9 months.

ARRIS began working with Skydio in March of 2020, and after a collaborative design process, we shipped working prototypes just a couple of months later. After another few months of functional testing and validation by Skydio and then a round of process optimization, industrial design improvements, and cosmetic upgrades, we were able to finalize the design and start Additive Molding™ production before the end of the year.

By bringing state-of-the-art materials and manufacturing methods into the UAV sector, ARRIS is expanding the boundaries of the possible for aerostructure designers. By bringing rapid innovation and fresh design and engineering thinking into this traditionally slow-moving industry, Skydio has raised the bar. Additive Molding™ of the Skydio’s X2 opens the door to a new chapter in aerostructure design, and we can’t wait to see what the world’s aerospace innovators will do next.

Press release: www.arriscomposites.com/skydio-press-release