ARRIS Raises $88.5 Million in Series C Funding

Led By XN, New Funding Enables ARRIS To Further Scale Production of Smarter, Lighter, Stronger & More Sustainable Products

Berkeley, CA, November 9, 2021 – ARRIS, the advanced manufacturer enabling the use of high-performance composites with new design latitudes for mass-market consumer products, transportation, and industrial applications, today announced that it has raised $88.5 million in Series C funding. Led by XN, the round saw participation from new and returning investors, including Modern Venture Partners, New Enterprise Associates (NEA), Taiwania Capital, Bosch, Valo Ventures, and Alumni Ventures Group.

The latest funding will be used to further scale the company’s global operations to fulfill an increasing demand for medium- to high-volume production of products requiring ARRIS’ unique design and manufacturing capabilities. ARRIS has now raised $147 million to date, which includes support from strategic investors across the global manufacturing space, such as Standard Industries, Chuo Malleable Iron, and an undisclosed portable electronics company, in addition to Bosch.

“ARRIS’ Additive Molding technology is transforming how next-generation products are made, enabling significant commercial and sustainability improvements across many of our most critical industries,” said Gaurav Kapadia, Founder of XN. “We are excited to partner with Ethan, Riley, and the entire ARRIS team as they dramatically expand the use of high-performance composite materials throughout the global economy.”

Founded in 2017, ARRIS pioneered the development of a patented end-to-end automated manufacturing technology that combines the best of advanced composites, additive and high-volume manufacturing methods to enable design latitudes not previously possible in mass-produced products.

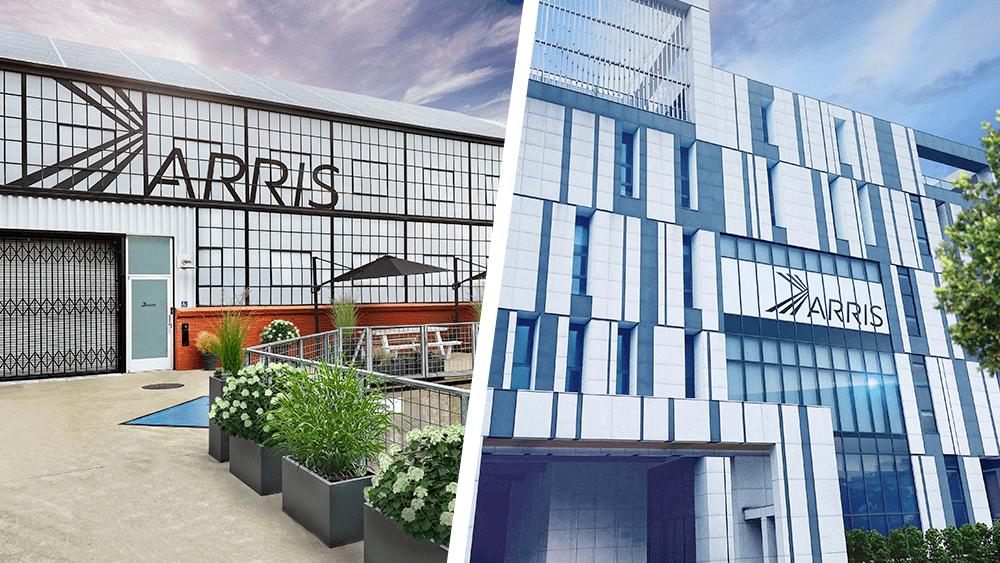

In 2020, ARRIS expanded its R&D facility in Berkeley, California, to include a dedicated new product introduction center for customers and U.S.-based production capacity. The ARRIS Taiwan production facility broke ground in 2020 and has nearly 45,000 square feet of additional capacity to serve key portable electronics customers who require product assembly overseas.

“Our company is at an inflection point with U.S. manufacturing in full swing, a new mass-production facility overseas, and customers winning design awards and receiving industry-wide recognition for their ARRIS-enabled products. The XN team possesses deep knowledge of how to scale durable businesses and is the ideal partner to help ARRIS achieve its next level of growth,” said Ethan Escowitz, CEO and Founder at ARRIS.

ARRIS serves world-class customers across the consumer products and sports, consumer electronics, aerospace, drone, government, industrial, and automotive industries. Recent partnerships exemplify the value ARRIS, and its technology can bring to customers:

-

- Leading unmanned aerial vehicle (UAV) manufacturer Skydio announced the use of ARRIS parts in its Skydio X2 drone. ARRIS’ parts allow Skydio to reduce weight and thereby increase the speed and range of its high-performance drones.

- The U.S. Army’s Combat Capabilities Development Command Ground Vehicle Systems Center (DEVCOM GVSC) announced a partnership with ARRIS to demonstrate significant vehicle weight reductions through part consolidation, topology optimization, and an aligned continuous carbon fiber composite structure.

- ARRIS announced a research project with global commercial aircraft manufacturer Airbus focused on the production of cabin brackets. The project aims to demonstrate significant reductions in aviation emissions by leveraging innovative manufacturing methods and materials, including composites. Replacing metal brackets with ARRIS’ continuous fiber composite parts can achieve more than 75% weight savings, which translates into significant fuel savings.

“We’re working with some of the most recognizable brands across industries to solve the hardest product engineering challenges that demand a new level of performance and design capabilities,” said Riley Reese, CTO and Co-Founder at ARRIS. “This next phase at ARRIS will broaden access to our design and manufacturing tools as we continue to expand the partnerships we have with the world’s most innovative companies.”

“We first met ARRIS in 2018, and were thrilled to have the opportunity to lead their Series A financing,” said Greg Papadopoulos, Ph.D., Venture Partner at NEA. “Our excitement has only grown having seen their customer traction, ability to execute, and leadership as a pioneer in the composites manufacturing space. This progress is a testament to the talent and perseverance of Ethan, Riley, and the team, and we are grateful to partner with them on this next phase of growth.”

With ongoing recruitment across all ARRIS locations, domain experts employ robotics, automation, material development, engineering disciplines, and software development to enable award-winning breakthrough product differentiation for customers. ARRIS was ranked as one of Fast Company’s “10 Most Innovative Manufacturers of 2021.” Additional recognitions include East Bay EDA’s 2021 Innovation Award in Advanced Manufacturing, the Business Intelligence Group’s 2021 BIG Innovation Annual Award, the Chicago Athenaeum’s GOOD DESIGN Award for 2021, and Red Dot’s 2020 Design Concept Award.

General Inquiries

info@arriscomposites.com

510.730.0067

Media Inquiries

Elizabeth Griffin-Isabelle

media@arriscomposites.com

Press Release as PDF [View]